In the automotive industry, the number of integrated circuits (ICs) is increasing every year, and are spreading to more modules to control the lighting, heating, and sensors of cars. The new paradigm of automotive design with more functionality and electrical control raises the question of whether the design is safe and whether the onboard electronics can withstand the transients common in automotive environments. In the automotive environment, the voltage can rise much higher than the IC specification or become a negative voltage. Transients are even more severe in 24V battery systems such as commercial trucks, forklifts and public transport vehicles.

The cause of the vehicle electrical control module being damaged by voltage is due to the failure of the voltage regulator (regulator), the influence of the ignition device, the switch of the high inductance load, the wrong cable connection, cable disconnection.

Such overvoltages take the form of voltage peaks for only a few milliseconds, occurring in coil ignition, up to a voltage of 350V.

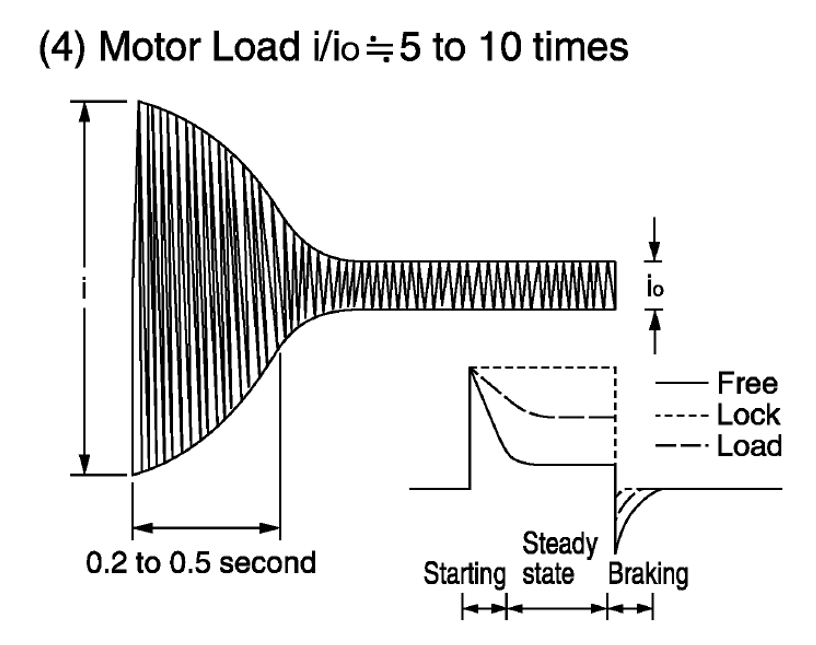

In the case of a relay loaded with a motor, a current of 5 to 10 times is generated in a very short moment, and a long battery cable also generates surge voltage and current in the same principle.

HydroLync has developed and patented a controller that protects the fan motor of the oil cooler for trucks and extends the service life in consideration of the electric characteristics of the automobile.

DC Motor Controller (DMC) drive method measures the temperature of the fluid flowing inside the matrix based on the temperature value set in the temperature sensor and turns OFF when it is lower than the set value. Allow the fluid flowing in the matrix to cool.

The features of DMC developed by HydroLync are as follows: